This website uses cookies to ensure you get the best experience on our website.

By continuing to browse the site, you are agreeing to our use of cookies.

To find out more about how we use cookies, read our Privacy Policy.

Demands on printed products are always increasing. As well as a perfect appearance, the frequently varying individual post-print processing requirements are also a major topic in this sector. There is a need for machine solutions which perfectly pack and promote products, while at the same time providing maximum flexibility and efficiency during processing. Increasingly the focus is also being placed on the sustainable use of films for packaging, while switching to a suitable paper packaging is also in demand.

As a response to the rapidly changing order structure for print products, and therefore the varying requirements in the post-print processing sector, Hugo Beck is setting the global standard for variability, flexibility, and efficiency. Our comprehensive portfolio of systems for print finishing, custom packaging, film packaging and paper packaging covers numerous requirements.

Our film packaging machines bag and shrink wrap many different products, and often different packaging types can also be flexibly combined. Our paper X hybrid machines are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. The paper X is our paper only basic packaging machine, without option to switch to film packaging.

All our machines can be rapidly converted from in-line to stand-alone operation, and mailing production can be quickly enhanced with new functions for compiling, inserting and packing. Personalisation, addressing, imprinting and feeding of booklets or multi-media articles are also easily provided through our systems.

The flexibility of Hugo Beck’s open system enables peripheral equipment to be easily integrated. Feeders of Hugo Beck can be moved freely and are provided with their own control and drive systems, making them multifunctional and capable of being used alongside other manufacturers’equipment. In addition, we also use robot systems for automated product infeed in the print and paper sector.

Recently, the revival of vinyl records has also been met by Hugo Beck with our machines packing vinyl, as well as CDs and DVDs. Our technology allows for a complete range of multimedia articles to be packed, such as TV accessories and boxes for smartphones.

Due to our extremely tight packaging with a highly precise fit of the film and hardly any film waste during production: When using continuous Hugo Beck machines, for example, there is no stop-and-go, and through highly precise sequencing and synchronisation of the transverse sealing unit with each product, gaps are minimised. This ensures high volume production outputs, as well as delivering an extremely close-fitting, precise and film-efficient packaging solution with an unrivalled and outstanding finish.

The tight fitting of the bag ensures a minimum film excess - an example would be 2 x 2.5 mm on a DIN A4 magazine and a production output of 8000 cycles/hour. In the case of shrink packaging, less film is then shrunk, which improves the packaging result and also reduces energy consumption.

The environmental profile of film packaging can also be optimised by making it as thin and light as possible. Packaging machines from Hugo Beck process extremely thin packaging and shrink films starting from only 7 µm without any problems

You have the choice between paper and film. A single Hugo Beck packaging machine can now deliver both film and paper packaging applications. The paper X hybrid advance is our most flexible and efficient Form Fill and Seal machine for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material.

Or you entirely opt for paper packaging in the future with a paper X packaging machine. Both uncoated and coated paper of various types can be used for producing bags.

Find out more in the full report about the complete paper packaging system and Kohlhammer's implementation of its sustainability strategy.

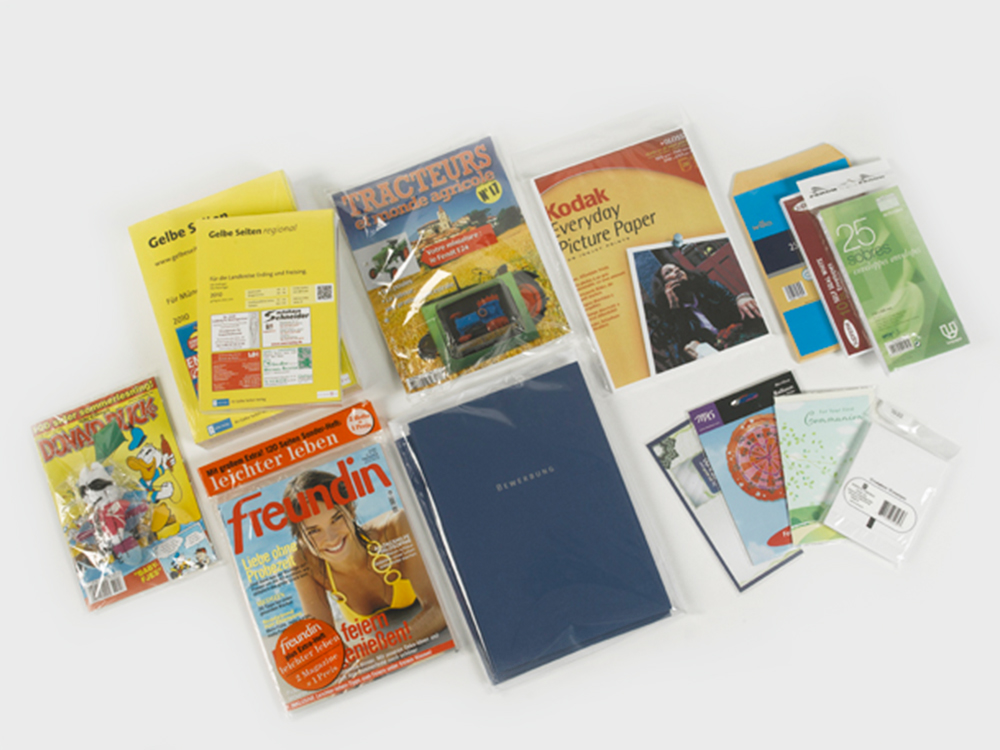

Magazines can be packed in a variety of ways. Either with side seal or overlap on top, as a bundle or individually, everything is possible. Especially in combination with side sealing, our extremely tight bag packaging can be produced, which saves film and eliminates the need for energy-intensive shrinking.

Magazines, inserts, various printed products, etc. are printed and personalised as shipping packaging, especially for subscriptions. The paper is uncoated and can be glued with hot melt. This paper packaging is produced with a paper X machine.

Magazines, inserts, various printed products, etc. can also be personalised in transparent paper as shipping packaging, especially for subscriptions. This paper packaging is produced with a paper X machine.

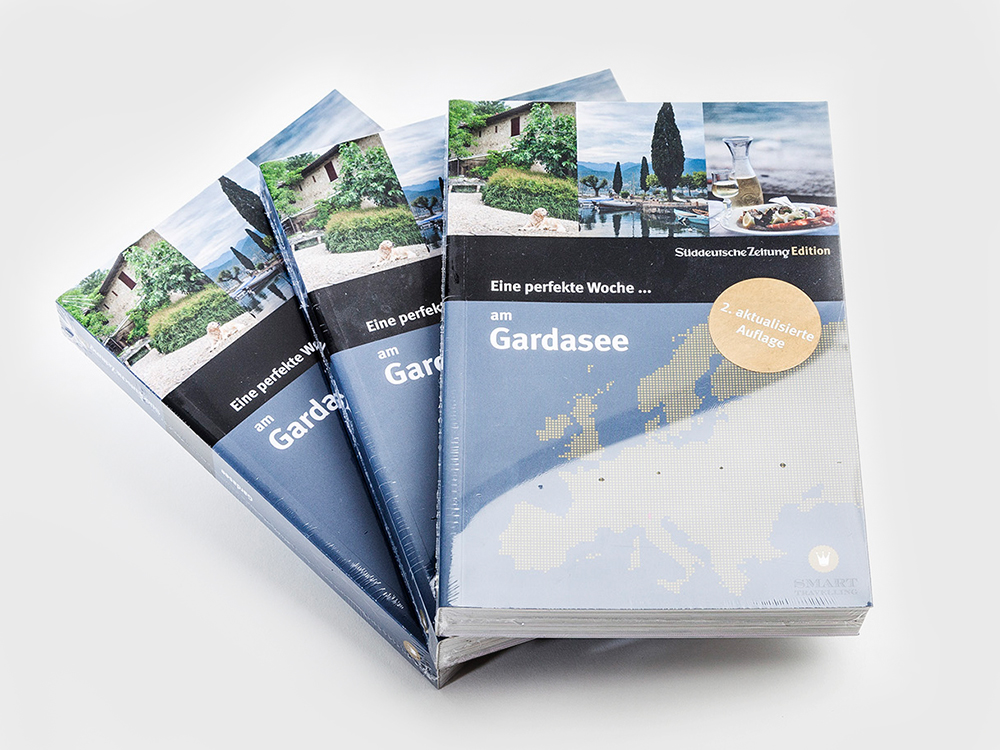

Catalogues and books are often stacked or individually wrapped in film after the actual production process. For perfect presentation in the store and for protection, a highly transparent PO film is often used. PE film is particularly suitable for packaging whole stacks.

Various printed products are packed as stacks on a flexo film packaging machine with shrink tunnel or with a sleeve wrapper. Single products are often wrapped in printed films, PE or PP films on a servo X machine at a high-speed performance with up to 15,000 cycles/hour. This also applies to books, which should convince with a high-gloss PO-film packaging.

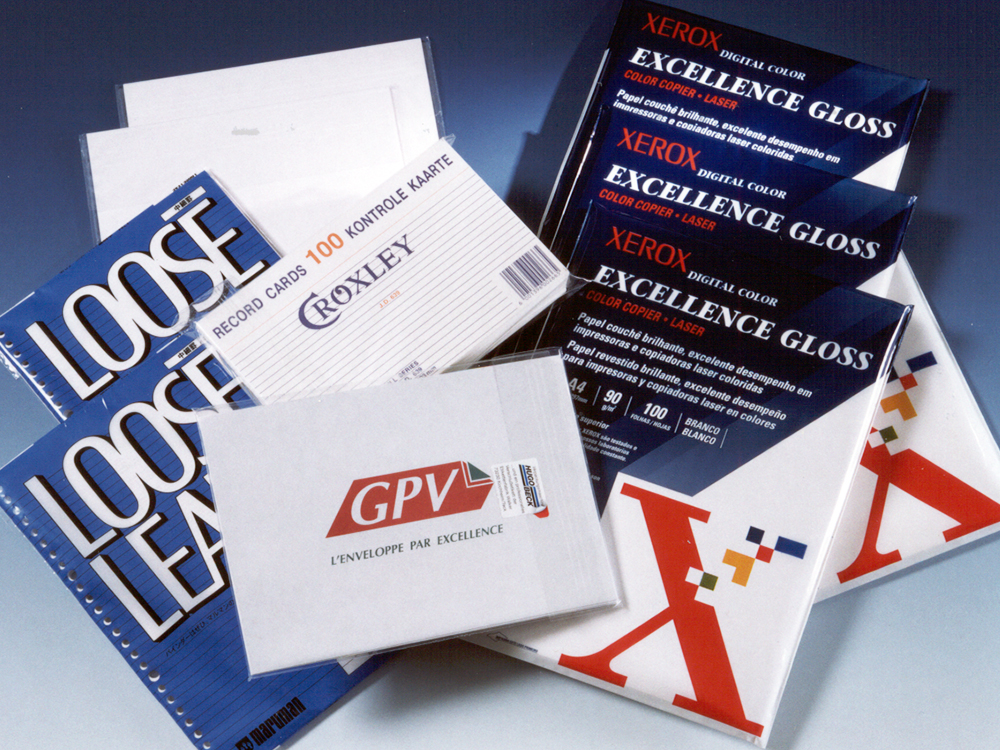

Greeting cards can be bagged with PP-films on the Hugo Beck servo X machines. Designs as double pack, hang pack with reinforced header or Euro hole hang pack are just as feasible as the use of a printed film.

Various multimedia items can be packed for better placement at the point of sale with a hang pack including a reinforced header on a servo X form fill and seal machine. The side seal creates a very tight bag and the reinforced header creates a very stable hang pack.

Individual gift and credit cards for example, are packed very tightly in transparent film with a servo X form fill and seal machine.

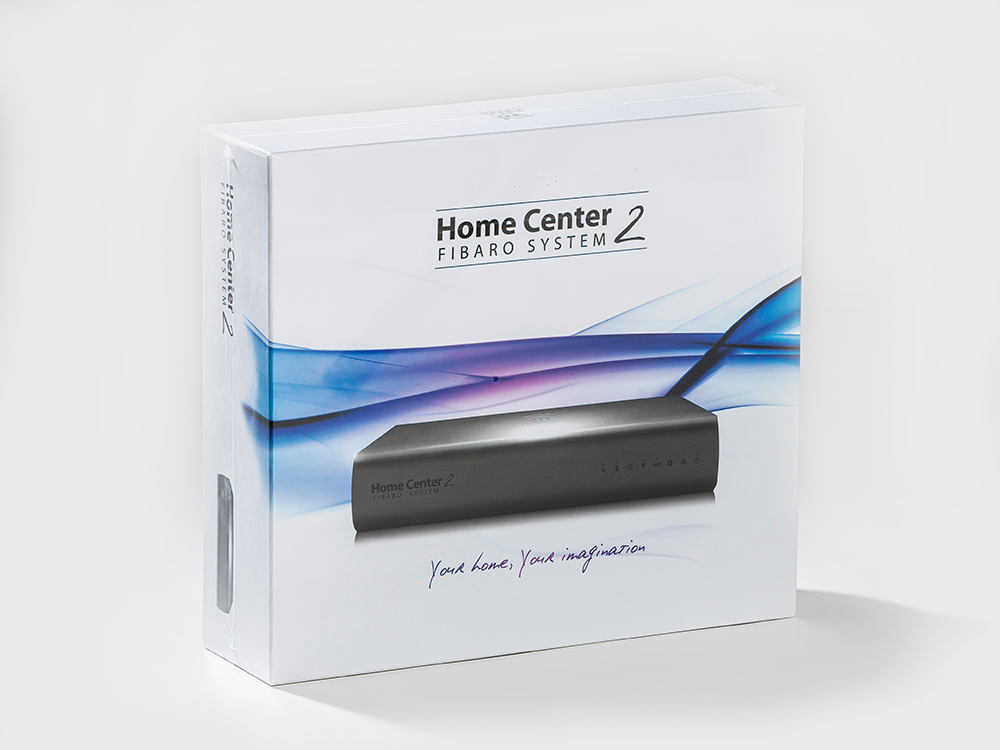

Boxes of various types are usually wrapped in film on a flexo 500 or servo X with side sealing. The products are then shrunk to create a precisely fitting and optically perfect shrink packaging.

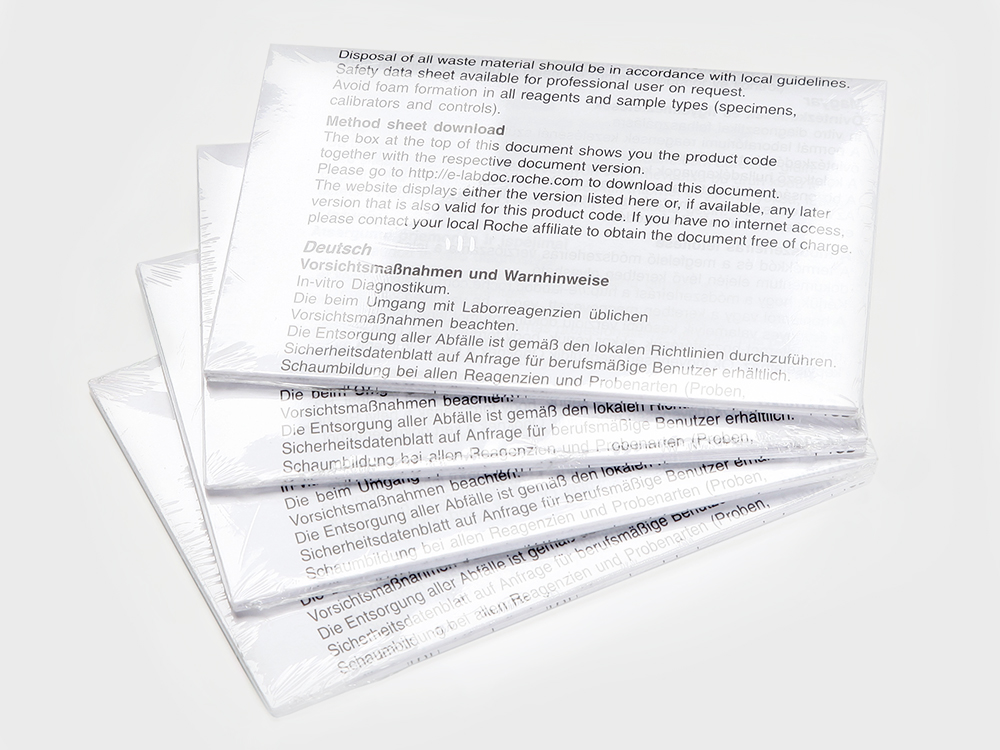

A special application is the packaging of package inserts in film. In addition to very tight packaging, speed and high reliability are particularly important. Usually, machines of the servo X series are used, where the products are first dispensed or counted by feeders and then fed into the packaging process.

On our form fill and seal machine servo X reclosable bags are produced, which are often used for envelopes, greeting cards, various papers, etc., to allow for re-use. For this purpose, a double-sided adhesive tape is for example inserted.