This website uses cookies to ensure you get the best experience on our website.

By continuing to browse the site, you are agreeing to our use of cookies.

To find out more about how we use cookies, read our Privacy Policy.

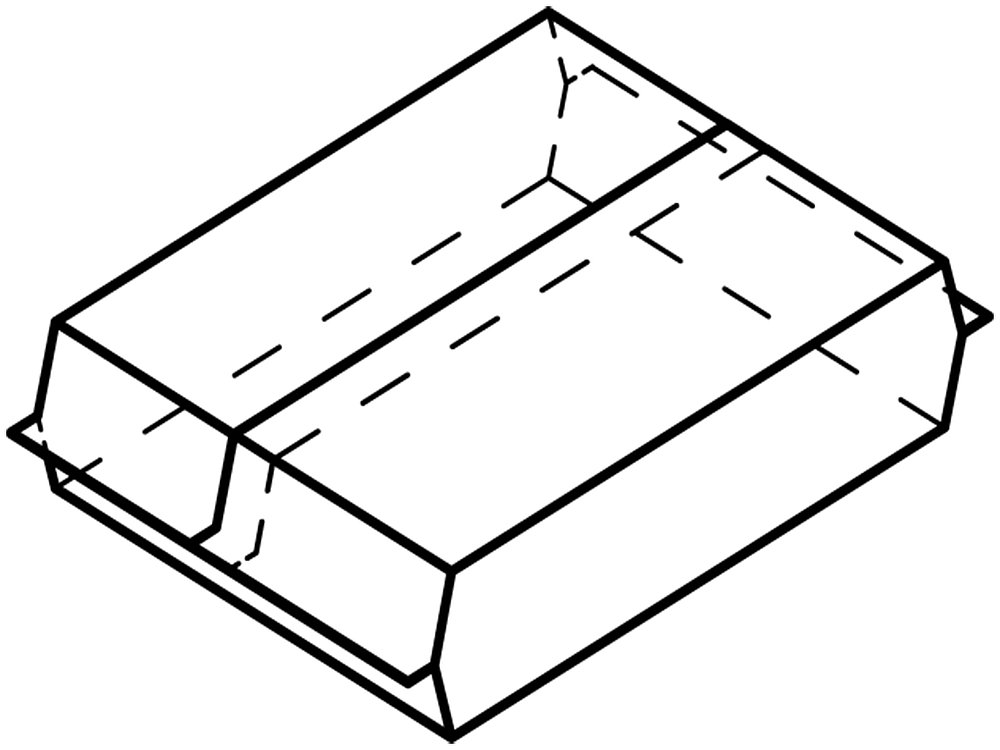

This paper packaging format, which is produced on the paper X Form Fill and Seal machine, is a high-speed application. A sleeve is formed by folding and gluing the paper at the top to enclose the product. The paper sleeve is then glued at the front and rear to form the finished pack. For this purpose, a glue line is applied in the infeed area of the paper, at right angles to the running direction. The product lies between the glue lines which are then pressed and sealed with a travelling cross sealing unit.

Production speeds of up to 12,000 cycles/hour are available with this packaging style.

As an option, Hugo Beck's machines automatically adjust the bag to the length of the product being packed.

Uncoated and coated paper from approx. 80 g/m2 to 130 g/m2 is used.

Magazines, inserts, various printed products, etc. are printed and personalised as shipping packaging, especially for subscriptions. The paper is uncoated and can be glued with hot melt. This paper packaging is produced with a paper X machine.

Magazines, inserts, various printed products, etc. can also be personalised in transparent paper as shipping packaging, especially for subscriptions. This paper packaging is produced with a paper X machine.

Dispatch packaging for single products or bundles in stacks with two glued sides and glued top overlap. Different products such as multimedia articles, vouchers etc. are packed. The suitable machine is the paper X. It wraps products of different width and height, especially the length is adjusted.