This website uses cookies to ensure you get the best experience on our website.

By continuing to browse the site, you are agreeing to our use of cookies.

To find out more about how we use cookies, read our Privacy Policy.

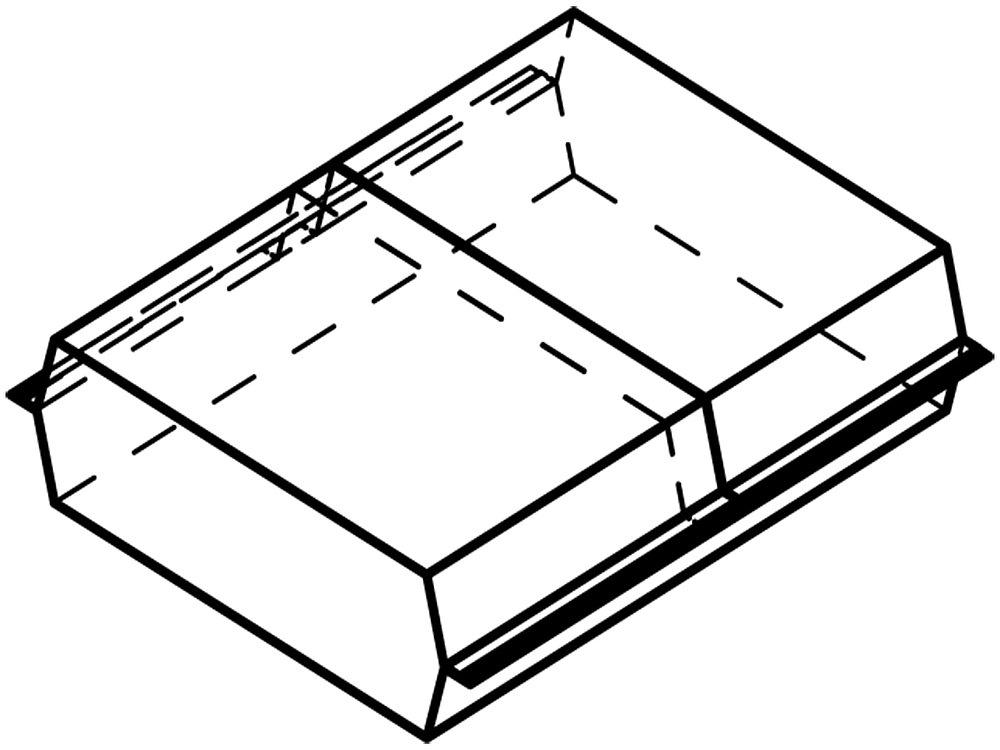

Various packaging techniques are applied to produce this paper packaging style with two sewn sides and glued top overlap.

Firstly, a paper banderole is placed around the product and hot-glued to the upper side. Any different product dimensions are detected by this packaging system with the dimension of the banderole adjusted to the product's length and height. This enables a mix of differently sized products can be fed to the packaging machine.

The lateral closing units automatically adjust to the product width for each cycle. At this stage, the still open sides of the paper banderole are closed laterally by means of sewing. Simultaneously, rotating knives cut off any excess paper.

This style of paper bag packaging is available with the paper e-com fit. The machine offers the possibility of storing two paper rolls of differing widths. After the product scan, the packaging machine intelligently decides how wide the paper web must be and selects the best paper roll to use, maximising efficiencies and minimizing paper use.

Uncoated and coated paper from approx. 80 g/m2 to 140 g/m2 is used.

Dispatch packaging or individual packaging with two sewn sides and glued top overlap. It can also be used as return packaging for various products, especially for textile goods. The suitable machine is the paper e-com fit. It adjusts automatically to different product dimensions and thus saves packaging material.

Dispatch packaging or individual packaging with two sewn sides and glued top overlap. It can also be used as return packaging for various products, especially for textile goods. The suitable machine is the paper e-com fit. It adjusts automatically to different product dimensions and thus saves packaging material.