This website uses cookies to ensure you get the best experience on our website.

By continuing to browse the site, you are agreeing to our use of cookies.

To find out more about how we use cookies, read our Privacy Policy.

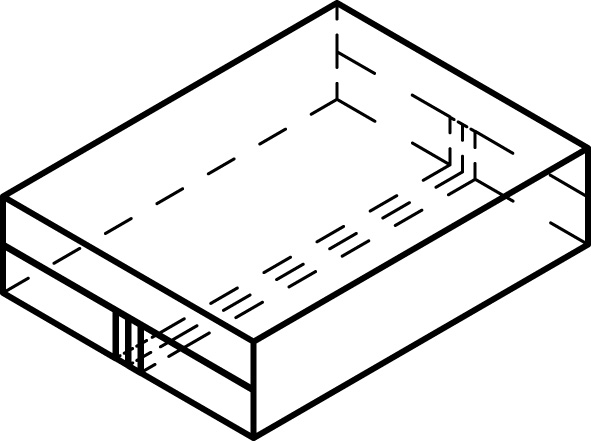

This overlap seal is applied in the middle of the product below. Hugo Beck uses the technology of seal welding or ionisation (with shrinking). This allows the overlap to be set centrally or laterally.

With fixed or adjustable forming shoulders, the film sleeve is optimally produced.

Speeds of up to 80 m/min are achievable with a bottom overlap and there is no film waste.

Our examples are applicable to many different products, product sizes and bundles. Let us find the perfect packaging solution for your product.

Chocolate box in extremely tight-fitting film with bottom overlap and ionisation. Produced with a Form Fill and Seal machine servo X. PO-film is used for sales packaging applications and PE-film for transport packaging. Printed films are also possible.

Paper towels are tightly bagged individually, in bundles and in stacks with our packaging machines. Register printed films can be used as well as PE, PO and PP films in different thickness. Suitable machines are a flexo 500 and servo X with side sealing or bottom overlap. Eurohole and double packs are possible. A further option are reclosable bags.

Tablecloths are tightly bagged individually, in bundles and in stacks with our packaging machines. Register printed films can be used as well as PE, PO and PP films in different thickness. Suitable machines are a flexo 500 and servo X with side sealing or bottom overlap. Eurohole and double packs are possible. A further option are reclosable bags.

Laminate and wood can be packed either in cardboard boxes or individually in film. In addition to the size and weight of the products, very high packaging speeds of up to 70 meters film per minute must be mastered. The machines used are flexo H, sleeve wrappers and above all servo X machines with bottom overlap and high automation incl. automatic film changing units and long shrink tunnels.