Material savings of approx. 15%

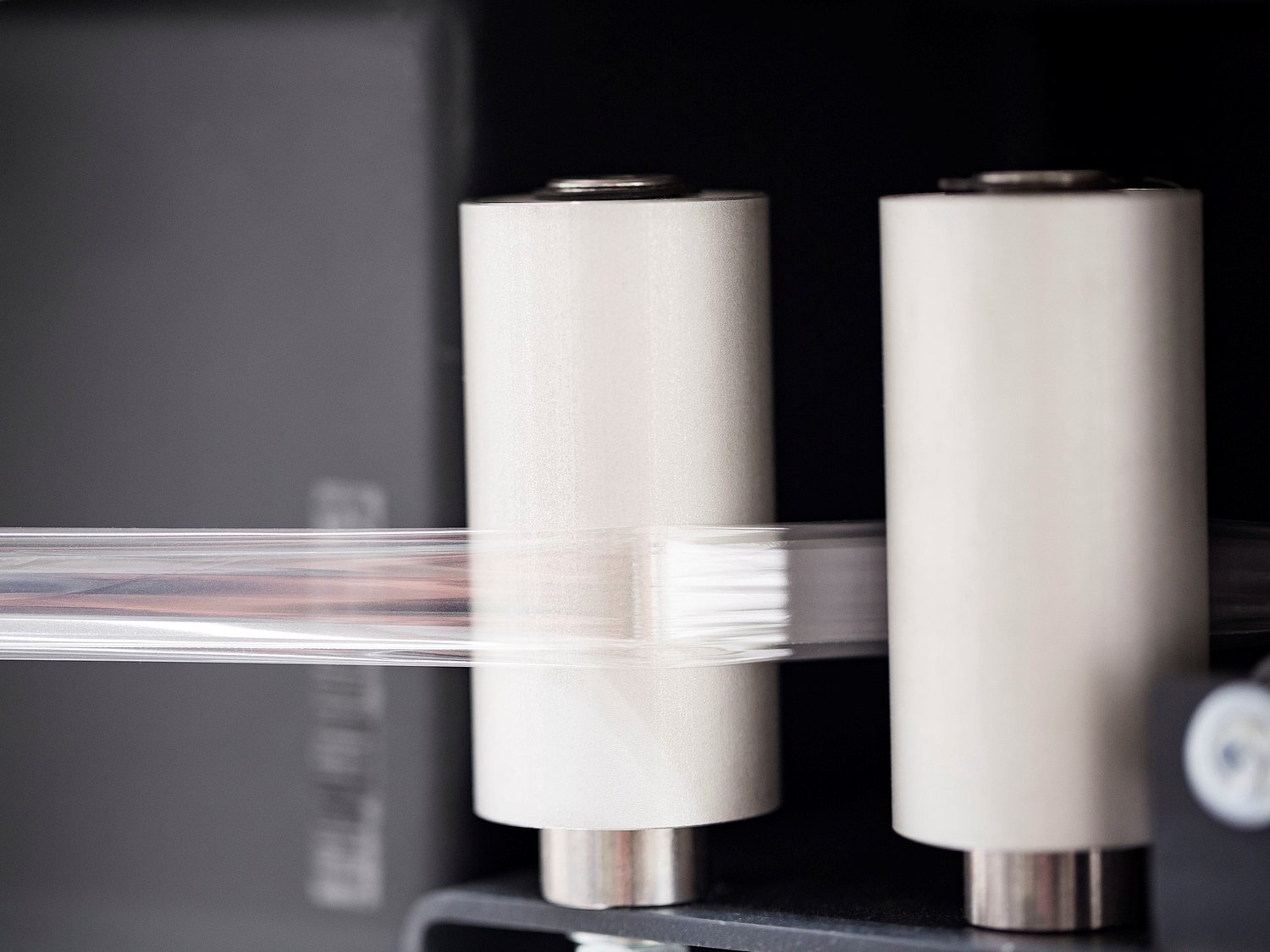

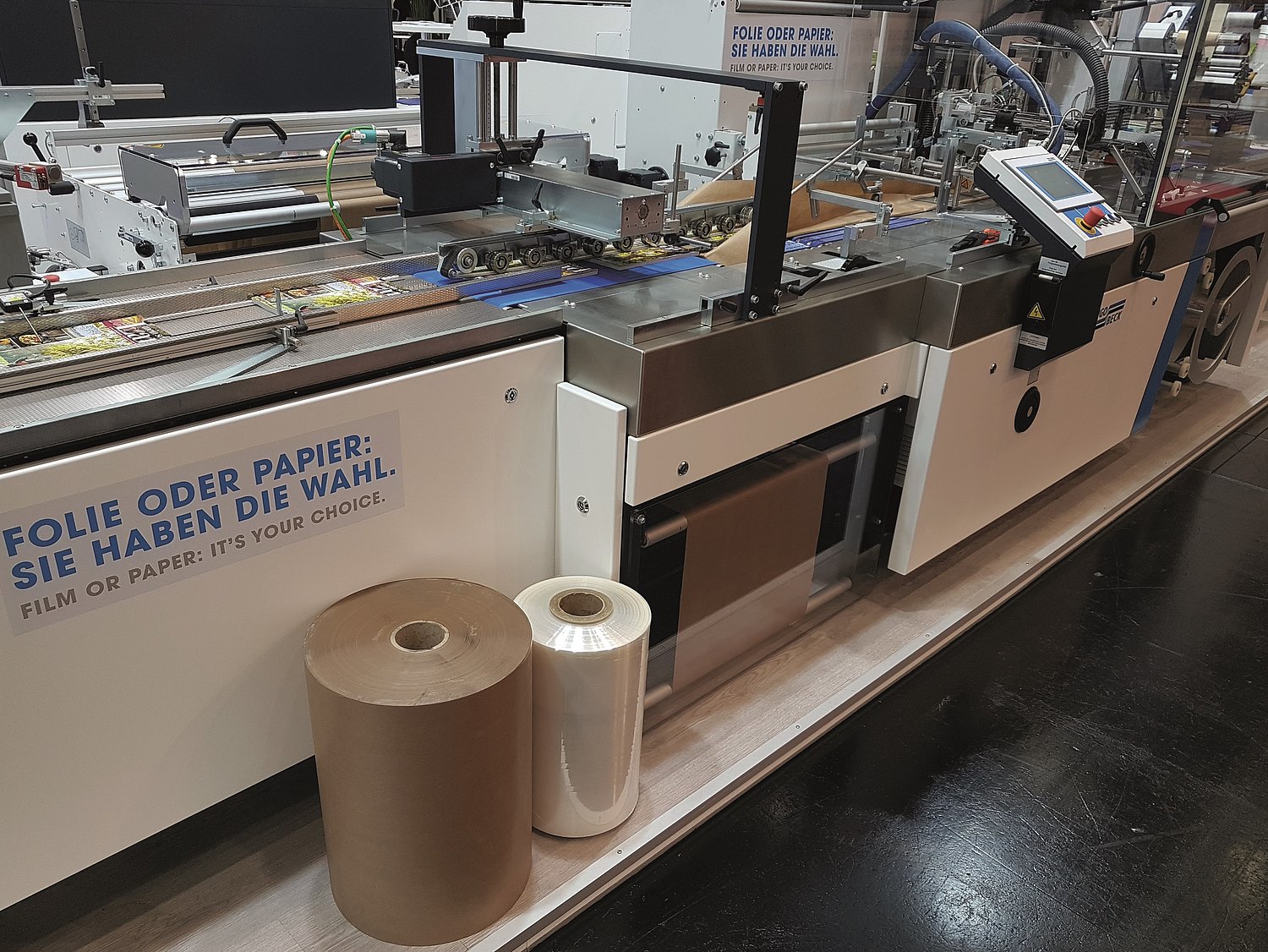

Due to our extremely tight packaging with a highly precise fit of the film and hardly any film waste during production, Hugo Beck's continuous servo X Form Fill and Seal machines can provide users with film savings of approx. 15%. For example, there is no stop-and-go, and through highly precise sequencing and synchronisation of the transverse sealing unit with each product, gaps are minimised. This ensures high volume production outputs, as well as delivering an extremely close-fitting, precise and film-efficient packaging solution with an unrivalled and outstanding finish. In the case of shrink packaging, less film is then shrunk, which both improves the packaging result and also reduces energy consumption.